This site is presented by the Angelica Mill, a small grower and processor of Tartary buckwheat. We attempt to provide accurate and up-to-date information about this nutritious but little-known traditional crop. Happy reading! Happy eating!

WHAT IS THE ANGELICA MILL?

After other pursuits both on and off our farm in Angelica, New York, we found our niche growing Tartary buckwheat. Because there is no commercial market for this species, we decided to mill and sell the flour ourselves. We’ve equipped the Angelica Mill with the necessary machinery, and gained some familiarity with it, but success will ultimately depend on the cooks and the diners willing to explore Tartary buckwheat’s culinary potential.

The Angelica Mill is our most recent venture on our farm outside the village of Angelica in western New York State. For the first decade after purchasing the farm in 1975, we had kept a small dairy herd. After selling our milk cows, we had raised some hay, grain, and dairy heifers. We then spent two decades off the farm, pursuing additional education and professional careers. Upon our return in 2006, we built a vacation rental cottage (The Granary), and established a farmers’ market business (the Catbird Griddle). In Angelica and nearby seasonal markets, we sold prepared foods that incorporated home-grown vegetables and fruits, as well as ingredients that had been grown or processed locally. Buckwheat pancakes proved a staple of the Catbird’s menu. Although the flour in our pancakes was purchased from a New York processor, I found buckwheat a particularly interesting plant. This crop was a side interest, because despite its luxuriant growth in our fields, it yielded too little seed to be profitable. By chance, while seeking ways to improve our yield of common buckwheat, I found that we could obtain better yields growing Tartary buckwheat. Since no commercial market existed for the latter species, we decided to mill and market our crop ourselves. After several years of acquiring and familiarizing ourselves with the necessary machinery, in 2017 we received a permit from New York State’s Department of Agriculture and Markets to clean, mill, package, and sell the Tartary buckwheat that we grow. We suspect that Tartary buckwheat is as unfamiliar to many cooks and consumers as it was to us. Therefore, we’re devoting this website to the history, cultivation, preparation, and nutritional value of this ancient crop.

Except for our Amish neighbors, farming depends less on collective labor than it once did. Nevertheless, we think of Angelica Mill not as our work alone, but rather as a grander collaboration. We depend on researchers around the globe for further exploration of the agronomy, physiology, and nutritional value of Tartary buckwheat. We depend on outfits like Big Bold Health to spread that nutritional story. We depend on cooks and diners to invent new recipes and to rediscover old ones. We look forward to hearing about your successes, and a few inevitable failures as well. Thanks for reading. Thanks for biting.

S. Beer, farmer and miller

P.S. Please cite this website if you appropriate text or images from it.

Our old dairy barn houses our grain cleaner and storage bins. In the foreground, Tartary buckwheat and common buckwheat (lower left) are in bloom.

WHAT IS TARTARY BUCKWHEAT?

Tartary buckwheat is a close relative of common buckwheat. Both are broad-leaved plants, not grasses like the true cereals; they resemble cereals because their seeds are predominately composed of starch.

Tartary buckwheat (Fagopyrum tataricum), like common buckwheat (F. esculentum), is a member of the plant family, Polygonaceae. Buckwheats accumulate edible carbohydrates in their seeds—in this respect resembling cereals. The latter, however, are members of the grass family (Graminae). Buckwheats and other broad-leaved species with seeds similar in composition to the true cereals are often referred to as “pseudo-cereals.” The seeds of pseudo-cereals (buckwheats, amaranths, quinoa, etc.) are often processed and consumed in the same ways as cereal grains—as porridge, leavened or flat breads, pancakes, cakes, noodles, and alcoholic beverages. But in addition to the seeds, other parts of the buckwheat plant are also edible—the flowers steeped as tea, and the greens (leaves and stems) steamed or stir-fried.

While all seeds require storage compounds to provide the energy and material for early growth, not all seeds rely primarily on carbohydrates to fulfill this vital function. Seeds high in fat content are found in species of some families, such as rape and mustard of the crucifer family. Proteins are the predominant storage compounds in pulses, the edible seeds from the legume family (Fabaceae). Edible seeds of different species vary not only in the relative quantities of carbohydrate, fat, protein, and minerals that they contain, but also in the specific compounds comprising each of these chemical groups. This compositional variability is found to a lesser extent among different cultivars of a single species, and—for a single cultivar—among lots harvested from different locations, and among harvests from multiple years at a single location.

As we describe the differences between buckwheats and cereal grains, or between Tartary buckwheat and common buckwheat, keep in mind that some of these generalizations have been drawn from a relatively small number of samples. Moreover, little is known about the dietary effects of some of the chemical compounds that have been identified in these samples, and even less is known about the nutritional effects of eating combinations of foods that have been cooked or otherwise processed. While expansive health claims have been made for foods containing buckwheat, we regard the current nutritional science as suggestive rather than definitive. Keeping this in mind, we’re excited by reports that consumption of Tartary buckwheat might strengthen the walls of capillaries, scavenge free radicals, lower cholesterol levels, combat diabetes, and prevent carcinogenesis. Let’s learn more.

Tartary buckwheat in bloom

HOW WE GROW IT

We grow Tartary buckwheat by sowing saved seed into a prepared seedbed early each summer. We cut the crop in early autumn, allowing it to dry in the field before combining (i.e., threshing and winnowing). We usually intercrop red clover with buckwheat, either plowing under the clover the following year, or else harvesting it as hay.

Tartary buckwheat (like common buckwheat) is a summer annual plant. In June or early July, we use a grain drill to plant seeds in rows seven inches apart. (We use the drill’s setting for about 150lb per acre of wheat seed. )

Planting (or “Drilling”) Tartary buckwheat

Under summer temperatures, both buckwheat species germinate and develop rapidly; flowers can appear within a month of planting, and seeds start to mature a few weeks later. Different varieties of buckwheat respond differently to the duration of daylight (or more accurately, to the duration of continuous darkness). Varieties that we plant will initiate flower buds during the long days of summer, and seeds are ready to harvest by mid-autumn. Other varieties will not bloom during long days; in milder climates (including regions of Japan) these short-day buckwheat varieties are planted later in the summer, and then are harvested later in the autumn.

Tartary buckwheat seedlings one day after emergence

Tartary buckwheat seedlings one day after emergence

While the vegetative growth stage of a buckwheat plant is relatively brief, flowering and seed ripening can continue for several weeks. At harvest, a single plant may still bear flowers and immature green seeds alongside mature seeds. By cutting the plants and allowing them to dry in the field for a few days, the ripening of immature seed can be hastened, thus increasing the yield of ripe seed during the subsequent “combining” operation. We use a self-propelled “swather,” or “windrower,” to cut buckwheat plants and lay them in windrows in the field.

Tartary buckwheat seed ripened in a windrow

Windrowing or “swathing” Tartary buckwheat

After the cut plants have dried, we use a tractor-pulled combine to pick them up, to beat the seeds from the stems (i.e., “threshing”), and then to separate the seeds from the straw and chaff (i.e., “winnowing”). In our area, many buckwheat growers wait for frost to kill and dry their buckwheat plants. They then employ combines with direct-cut grain headers; these machines can reap, thresh, and winnow in a single pass over the field.

The combine threshes Tartary buckwheat seeds from stems and separates the threshed seed from chaff

Tartary buckwheat seeds after separation from chaff by the combine

While tartary buckwheat is considered more tolerant of cold temperatures than common buckwheat, both these species are sensitive to freezing temperatures. Therefore, the entire growth cycle must be fit within our frost-free growing season—from late May through September. Nevertheless, we find opportunities to multi-crop or intercrop other species with Tartary buckwheat. We usually seed red clover (Trifolium pratense) simultaneously with buckwheat. Both Tartary buckwheat and clover require a fine seedbed without much crop residue on the surface. Before planting, we usually turn the soil with a moldboard plow (a system called “complete tillage”). At a minimum, we make a couple passes with a disk harrow and a spring-tooth harrow to break up residues and smooth the field surface. Seeding is followed by packing, to assure good contact between seeds and soil particles. This is important in our coarse and porous gravelly soils, because soil particles provide the seed with the water necessary for germination. While buckwheats can be grown on a wide range of soil types, their relatively weak root systems develop particularly well in our gravelly and sandy loams (of the Chenango, Tioga, and Unadilla soil series). These soils resist both crusting and compaction; once seeds germinate, roots are well aerated and can penetrate easily.

Like buckwheat, red clover germinates rapidly. This is essential, because the buckwheat plants quickly establish a solid canopy, limiting the light that reaches the soil surface. So although buckwheat prevents the germination and growth of most small-seeded weeds, red clover generally can maintain slow growth underneath the canopy, and be well established by the time we harvest buckwheat. The clover overwinters, to be cut for hay the following year, or else to be plowed under as a “green manure” in the spring. Clover is a leguminous crop that hosts nitrogen-fixing bacteria in its root system. By “fixing” atmospheric nitrogen (N2), clover replaces the forms of nitrogen that had been taken up and utilized by the buckwheat crop.

Plowing down a vigorous stand of red clover in June, prior to planting buckwheat

If we harvested Tartary buckwheat by the end of September, the same field could then be planted to winter wheat or winter rye. Seeded as late as November, these crops emerge before winter, then resume growth the following year. In previous years, we would then harvest wheat or rye in July. However, when machinery or storage spaces were used for cereals, a few kernels inevitably remained to contaminate the subsequent buckwheat crop. Therefore, we no longer allow cereal crops to produce seed in our fields. If we grow them, we plow them under as green manure, before they can set seed.

WHY NOT ORGANIC? WE ARE!

For years we controlled weeds, insects, and pathogens without using synthetic pesticides. We also avoided synthetic nitrogenous fertilizers, the manufacture of which depends on fossil fuel. Although all of the nitrogen, phosphorus, and potassium for our buckwheat was supplied from plant or animal manures, we had not sought certification under the US Department of Agriculture’s National Organic Program (NOP). Then in 2020, we applied for and received certification through NOFA-NY. Indeed, why not?

The pillars of organic agriculture are the use of naturally-occurring substances 1) to maintain soil fertility, and 2) to prevent unacceptable losses to diseases, insect damage, and weed competition. But besides designating which fertilizers and pest-control substances may be applied, the USDA’s Organic standards stipulate other practices that are required for organic certification: avoidance of genetically-modified (GMO) varieties; use of organically-produced seeds; spatial buffers separating organic fields from “conventional” fields; and segregation of organic and conventional crops during harvest and post-harvest processing. The extensive record-keeping seemed daunting, so for years we farmed without organic status. Then in 2020, we filed the application with NOFA-NY, passed the on-site inspection of our fields and mill, and added the USDA’s Organic emblem to our products. Long overdue!

We mentioned above that we use red clover, a leguminous crop, to supply nitrogen to our fields. This plant source of organic nitrogen is important, because most animal manures contain a lower ratio of nitrogen to phosphorus than crops require. To supply all of a crop’s nitrogen requirement with animal manures would therefore over-supply that crop with phosphorus. The surplus P could be carried away by erosion, and rather than fertilizing succeeding crops, could end up fertilizing algae in streams or lakes. Alternatively, we could augment the N available from animal manures with “chemical” nitrogenous fertilizers. We have avoided the latter, however, because their manufacture consumes large quantities of natural gas. (In fact, the industrial production of nitrogenous fertilizer constitutes agriculture’s largest consumption of fossil fuels.) Moreover, the nitrogen in plant residues is released more gradually than that in “chemical” fertilizers; therefore, less might escape to surface waters (as nitrate) or volatilize into the atmosphere (as ammonia or nitrous oxide, the latter a potent “greenhouse gas”).

Regarding the control of diseases and deleterious insects in our fields of Tartary buckwheat, we have never experienced crop losses that required any response. This might be due to the relatively primitive state of domestication of this species. Resistance mechanisms in plants—whether the growth of specialized morphological organs or the accumulation of noxious or toxic compounds—usually entail some metabolic cost. Many domestic species have been bred to maximize yield—that is, to maximize growth of those parts of the plant that we eat—under conditions with low weed competition or insect infestation. Under these nearly ideal conditions, artificial selection favors lines that expend less energy on resistance mechanisms that do not contribute directly to that yield. For example, Tartary buckwheat has a relatively low seed yield per acre—about a third of the seed yield of corn (maize) grown in our area. Much of that difference in yield is due to the different chemical pathways by which the two species incorporate atmospheric CO2 (i.e., “C3” versus “C4” metabolism), and due also to the longer growth cycle of corn. Still, that yield difference might also reflect the intensive scientific breeding effort that has contributed to higher corn yields. Tartary buckwheat, in contrast, has undergone little scientific breeding. Therefore, this species might expend more energy on those disease- or insect-resistance traits that it has inherited from its wild progenitors.

In our fields, Tartary buckwheat generally competes very successfully against weeds. As stated above, buckwheat seeds germinate quickly, and young plants form a solid canopy before many weeds can get started. Moreover, both common and Tartary buckwheat have “allelopathic” properties–that is, plant residues in the soil can suppress the germination of seeds of some other species. We do not apply any herbicides to our crops. We plant seed that we have harvested and cleaned ourselves. Therefore, we do not introduce new weed seed into our fields. We do not apply any fungicides or other pesticides to the seed that we plant.

HOW WE CLEAN TARTARY BUCKWHEAT

The crop is cleaned in a vintage two-screen cleaner, designed to remove coarse chaff, fine debris, and light kernels. Before and afterward, it is dried with ambient air. Prior to milling, the grain passes through a de-stoning machine.

Once we’ve harvested our Tartary buckwheat, we elevate the seeds into bins on the upper floor of our former dairy barn. By spreading the seed no more than a couple feet deep, we can dry the seeds with ambient air (i.e., without pre-heating the air by combusting natural gas or fuel oil). The buckwheat seeds are then cleaned with a vintage Model 9 Clipper Cleaner (A. T. Ferrell Company, Bluffton IN). This is an air-screen cleaner with two inclined perforated metal screens. From a receiving hopper (upper left in the photo below), the seeds are fed onto the upper “scalping” screen. A reciprocating motion causes the seeds to fall through this screen, over which larger “trash” (mostly stems and leaves) flows to a discharge chute. The seeds drop onto the “sizing” screen, through which dirt, fine debris, and unfilled seeds pass to a second discharge chute. As the clean seed is shaken off the lower end of the sizing screen, an updraft from the cleaner’s fan removes any remaining light debris from the falling stream of clean grain. A cross conveyor (discharge end visible at lower right in photo) beneath the Clipper transports the clean grain to an elevator, which carries it to our clean grain bins.

Our Clipper Model 9 grain cleaner

Our Clipper Model 9 grain cleaner

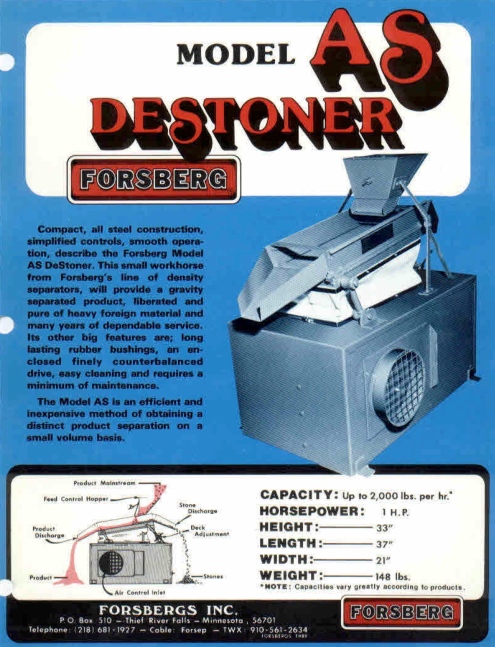

As needed, the cleaned buckwheat grain is loaded into drums for transfer to our milling room in another building on the farm. There, the grain is passed first through a Model AS de-stoner (Forsberg Co., Thief River Falls MN). As in the air-screen cleaner described above, in this de-stoner the grain drops from a receiving hopper onto an inclined screen deck. The reciprocating motion of the deck propels heavy objects like stones upward along the deck’s coarse surface. Air blowing up through the deck lift the seeds enough so that gravity carries them down the incline. With stones removed, the clean buckwheat is now ready to mill.

Cleaned buckwheat must be de-stoned prior to milling

HOW WE MILL TARTARY BUCKWHEAT

We grind whole seeds in a stone mill. With subsequent sifting we remove the larger hull fragments. Using a finer screen, we then separate out our “pale flour;” this comprises much of the endosperm–the starch-filled cells from the seed’s interior. What remains after sifting are particles of intermediate size: larger fragments of endosperm, small bits of hull, and the other tissues of the groat. We package this material as “bran.”

In technical parlance, a mature buckwheat seed is an “achene” [pronounced “a-KEEN”]. Its hard dark-colored hull (“pericarp”) encloses the buckwheat “groat.” The latter comprises a thin seed coat and the softer, whitish embryo and endosperm within. The embryonic axis is located at the apex of the roughly pyramidal achene; its cotyledons (proto-leaves) enwrap the endosperm. The endosperm comprises an outer one-cell-thick layer of living cells (the aleurone), and a central portion of starch-filled dead cells. Steadman et al. (2001a) have explained which tissues end up in which products during common milling operations.

The hulls of common buckwheat can be detached from the groats by impact milling. Sometimes this is facilitated by prior heating with steam or hot water, followed by slow cooling and drying—a process called “hydrothermal processing.” Empty hulls are then removed by air separation, after which the intact groats are separated from broken pieces (“grits” or “semolina”) by screening. The intact pyramidal groats are familiar to many, as they are commonly roasted and sold as “kasha.” Alternatively, those whole groats can be ground with steel roller mills or stone mills. Once pulverized, the central endosperm and some portion of the embryo are separated by sifting and sold as pale “fancy” flour. The groat’s outer layers—seed coat, aleurone, and much of the embryo—are sometimes recovered as “bran.” Alternatively, the bran plus remaining endosperm fragments can be cycled again through the mill to produce a darker flour, sometimes labeled as “supreme flour.”

Alternatively, if whole achenes with hulls intact are ground, then three fractions can be recovered: the finely-pulverized (“fancy”) flour, large flattened pieces of hull, and everything that remains of intermediate size. The last fraction is usually recycled through the mill and sifter, each time obtaining another fraction (or “break”) of flour. Because flours from successive breaks contain different percentages of embryo, endosperm, and maternal tissues, and because these fractions all differ in their chemical composition, each cycle of milling produces flour with unique characteristics. In general, the higher the percentage of endosperm, the paler the flour and the greater its concentration of starch. The higher the percentage of embryonic tissue, the greater the concentrations of protein and fats (Steadman et al., 2001a). The greater the percentage of hull that is retained, the greater the concentration of fiber, and the darker the flour.

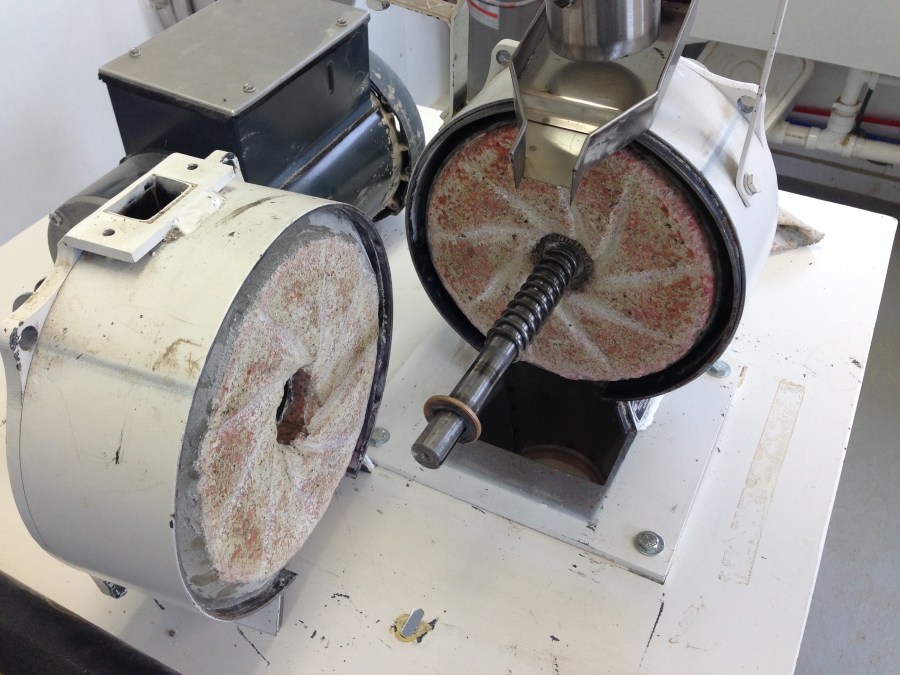

Compared to common buckwheat, the hulls of Tartary buckwheat adhere more tightly to the enclosed groat. Therefore, it is difficult to remove the hulls while leaving the groats intact. In Asia, the hydrothermal processing mentioned above is employed to recover whole groats. Roasted, these are packaged and sold as “Tartary buckwheat tea.” At Angelica Mill, we haven’t attempted to produce intact groats. Instead, we produce Tartary buckwheat flour by processing whole seeds (i.e., still in hulls) through a small stone mill (Meadows Mills, Wilkesboro NC). This mill operates on the same principle as did the larger wind- and water-powered flour mills from centuries past: grain passes between one side of a rotating disk-shaped stone (the “runner”) and the facing side of a second stationary stone of the same shape (the “bed stone”). As the seeds move centrifugally (from a central inlet outward toward the circumference of the two stones), they are pulverized into ever-smaller pieces. After falling off the edge of the stones, the mix of hull fragments, fines, and flour is then collected for sifting. Our mill has 8”-diameter stones mounted on a horizontal shaft. By limiting the speed (RPMs) of the runner stone, we seek to minimize the heating of the flour due to friction, and thus to minimize any thermal degradation of the flour’s constituents.

Meadows 8″ stone burr mill

Disassembled mill showing bed stone (L) and runner (R). Seeds enter the port in the mill housing above bed stone and pass along that stone’s central channel, which surrounds the horizontal drive shaft. After passing between opposing surfaces of bed and runner, the pulverized seeds exit through the port in the housing below the runner.

During the first pass through the mill, the groats are largely pulverized, but the hulls come off in large flattened pieces. We use a circular vibratory sifter (Vorti-siv model RVM-15, MM Industries, Salem OH) with a 10-mesh screen to separate those hull fragments from the mix of finer particles. Hulls make up about 25 percent of the weight of the seeds. A subsequent sifting through a 50-mesh screen separates the pale flour, which comprises about 35-40 percent of the weight of whole seeds. The residue that won’t pass through this 50-mesh screen–containing some recognizably dark flecks of hull, but mostly small fragments of endosperm and bran–we package as “Tartary buckwheat Bran.” We previously marketed this material as “Grits,” because pieces of endosperm (true grits) were a major constituent. However, we revised our label because the term “grits” confused consumers who were seeking “groats”–dehulled whole kernels.

By cycling bran back through the mill’s stones and then the 50-mesh sieve, a fraction can be reduced to a dark and stronger-tasting flour. We discontinued processing and selling such “dark grade” Tartary buckwheat flour, because the yield was small for the time expended. However, some customers have expressed disappointment that we don’t offer a whole-grain flour. Subsequently, we were able to convert almost all of the bran to “dark grade” flour by pulverizing it in a hammer mill. However, because of the time require to dismantle and clean the hammer mill, we’ve suspended the production of dark flour. Sorry, but we don’t offer an option of a whole-grain Tartary buckwheat flour at this time. Such a product is available from Big Bold Health

Sifting hulls after grinding Tartary buckwheat seeds

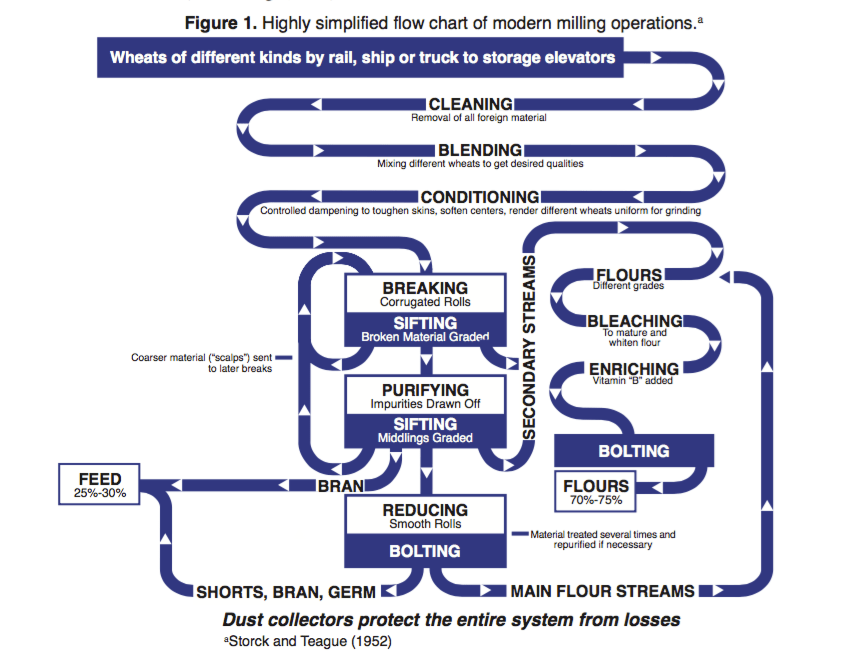

As the photos and description above indicate, ours is a very small-scale operation. Until we’ve established a clientele for our flour, we must invest in small equipment. Low-volume usually means labor-intensive. And when the small machinery is also old, repairs and maintenance consume more time. By comparison, below is a diagram of a “modern” steel-roll wheat milling operation (first published in 1952). We can’t offer a price competitive with highly-automated freight-train-scale agribusiness. Instead we can promise attention to detail–every step of the way, from planting the seed to sewing up the bag.